ATOMIZATION

Producing

droplets of specific size and surface area by atomization

is the most critical step in the spray drying process.

The degree of atomization, under a set of spray drying conditions,

controls the drying rate, and therefore the required particle

residence time, and therefore the spray dryer size. All of the

atomizing techniques can give good average particle size

control, but there are major differences in the particle size

distribution created. The most commonly employed

atomization techniques are:

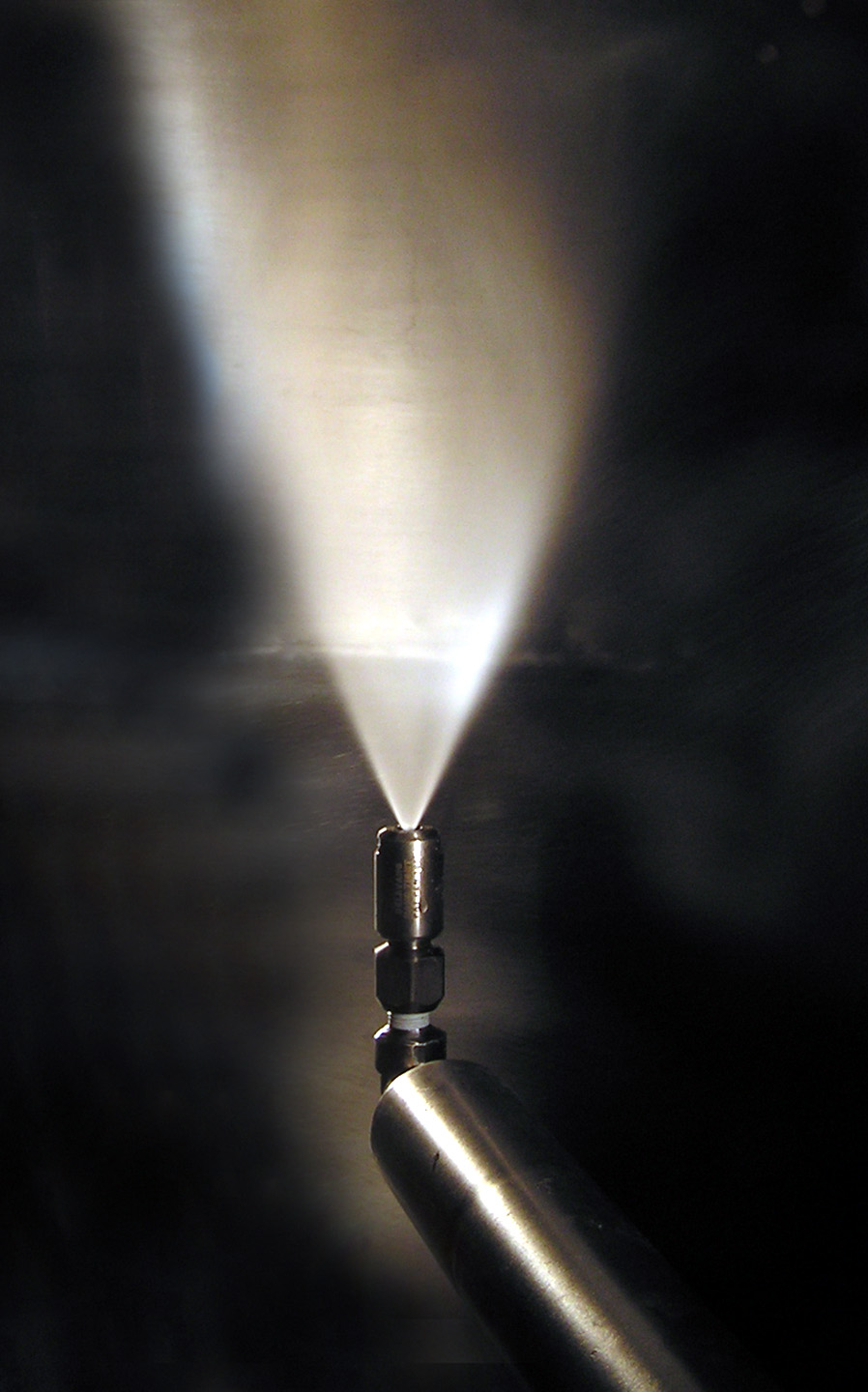

Pressure Nozzle Atomization

|

|

Pressure Nozzle |

- A

spray is created by forcing the fluid through an orifice.

The energy required to overcome the pressure drop is

supplied by the spray dryer feed pump.

- The

narrowest particle size distribution is possible with this

technique. Must be used when minimization of

“fines” is important to the product.

- The average particle size produced, for a given feed, is

a function of the flow per nozzle and the spraying pressure.

-

Spraying pressure depends on feed characteristics and

desired particle size, and can range from 300 to 3,000 psig.

- The

most energy efficient of the atomization techniques.

- Requires a positive displacement, high pressure feed

pump, such as a plunger pump or a piston/diaphragm pump.

- Requires

routine changing of the nozzle internal pieces, usually made of

tungsten carbide. Changing schedule depends upon the

application.

- Requires a minimum of approximately 0.10 GPM feed rate,

depending upon the size of un-dissolved particles in the

dryer feed, due to potential plugging with the small orifice

required.

- With

multiple nozzle spray dryers, a problem with one nozzle does not

shut operations down.

- Control of spray dryer wall buildup can be achieved

through variations of the spray angle.

Two-Fluid Nozzle Atomization

|

|

Two-Fluid Nozzle |

- A spray is created by contacting two fluids, the feed and a

compressed gas. The atomization energy is provided

by the compressed gas, usually air. The contact can

be internal or external to the nozzle.

- A broader particle size distribution is generated.

- The average particle size produced for a given spray

dryer feed is

primarily a function of the feed flow per nozzle, and the

compressed gas rate and pressure.

- The least energy efficient of the atomization techniques.

- Useful for making extremely fine particles (10-30 micron) because

of relatively high wear resistance. Also for the small

flow rates typically found in pilot scale dryers.

- Requires periodic changing of the air and liquid caps.

- Can typically use any type of spray dryer feed pump.

- Control of the spray angle is limited.

Centrifugal Atomization

- A spray is created by passing the fluid across or through a

rotating wheel or disk. The energy required for

atomization is supplied by the atomizer motor.

- A broader particle size distribution is typically generated.

- The average particle size for most products is limited

to under 100 micron due to wall build up issues.

- The average particle size produced for a given feed is

primarily a function of the diameter and RPM of the wheel.

- Requires relatively high gas inlet velocity to control wall

buildup, which can increase the amount of fines

produced.

- Can generally be run for longer periods of time without

routine maintenance.

- Usually the most resistant to wear. Requires periodic

changing of wheel inserts, usually made of tungsten

carbide.

- Control of wall buildup is minimal, due to direction of spray

(horizontal) and broad particle size distribution, forcing

the dryer to be relatively large in diameter.

- Capital cost of the atomizer is typically high.

Comparatively larger diameter spray dryer can increase capital

cost. As with any high speed rotating machine,

maintenance costs are high. Design of dryer roof and

atomizer support add to fabrication cost.

- A problem with the atomizer will shut down spray drying operations.

Particle Size Distribution Comparison

Atomization Energy Example Comparison

|

(Based on Atomizing 10 GPM of Feed

to 70 Micron Droplets)

- Pressure Nozzle: Feed Pump @ 1200 psig = 10 HP

Total

- Centrifugal Atomizer @ 9000 RPM @ 25 HP,

Feed Pump @ 30 psig @ 3 HP = 28 HP Total

- Two-fluid Nozzle: 180 SCFM Compressed Air @ 80 psig

@ 30 HP, Feed Pump @ 80 psig @ 5 HP = 35 HP Total

|

Mesh to Micron Conversion

Back to Top

|